ABOUT US

We ensure compliance through strict measurements and diverse inspections - both after the various production steps and at the end of the entire process. To do this We use the most Up-to-date measurement technology and endurance test plants - as well as the practical component test by hand.

To perform the Voltage Piece Test, our tools are submerged in water for 24 hours. After this period they are then electrified with 10,000V AC for three minutes. Neither a spark over nor a disruptive discharge through the insulation may occur. If and when no current is detected, they are approved for up to 1,000 V AC (and 1,500 V DC) thus earning the VDE Certification.

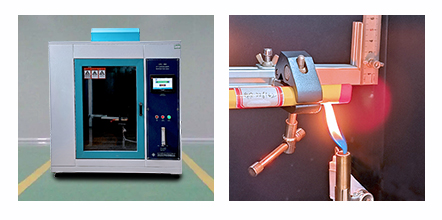

When exposed to a 20mm-height flame for 10 seconds, if the flame height on insulating material was less then 120mm, then it passed the marking durability test.

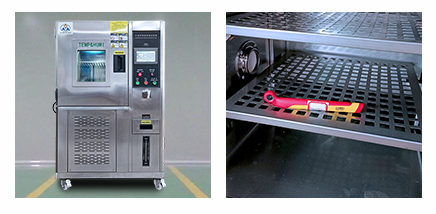

The tools are first cooled down to -40 °C, then during this process, the insulating material must retain its toughness so that it does not break when subjected to impacts and jolts.

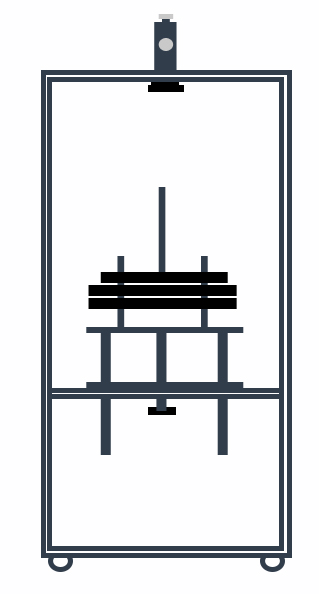

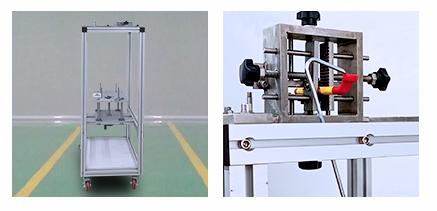

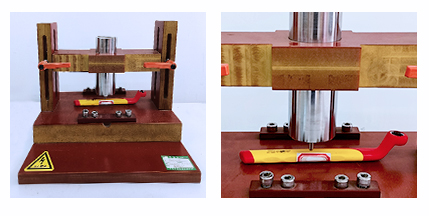

The adhesion of the insulating material coating is tested by applying a tensile force of 500 N following storage for 2 hours, at 70°C. The insulating material must continue to be firmly connected to the basic tool to pass when doing so.

No disruptive discharge may occur at a pressure load of 20 N, a temperature of 70 °C, and a 3-min high-voltage test after 2 hours.

Immerse your label in isopropyl alcohol for 3 minutes. Remove the label from the alcohol. Then, use a rag soaked in water to scrub for 15 seconds. If the label impression did not fade or scratch off, it has passed the marking durability test.